Calcined Petroleum Coke: Applications and Importance in Metallurgical Industries

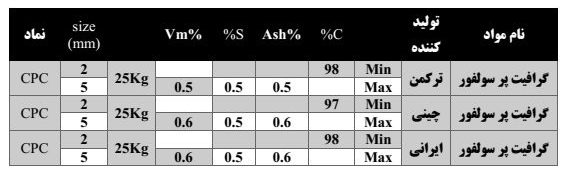

Graphite is one of the most significant allotropes of carbon available in two forms: low-sulfur graphite and high-sulfur calcined petroleum coke (CPC). Hamgaman Sanat Company provides these valuable materials to its customers. These products have a wide range of applications in metallurgical industries, including enhancing steel hardness, producing industrial electrodes, and reducing steel and metal oxides through carbon reduction.

High-Sulfur Calcined Petroleum Coke is the primary product of the calcination process. This material is crucial as a carbon source in steelmaking and cast iron foundries.

Calcined petroleum coke generally appears in granular, porous form with a matte black or gray color. In some cases, it may appear shiny due to crystallization during the calcination process.

**Calcination Process**: Calcination involves heating materials to high temperatures to induce a chemical change. This process is performed to remove volatile substances and increase the purity of the materials.

**Applications of High-Sulfur Calcined Petroleum Coke**:

- **Enhancing Steel Hardness**: Adding graphite to steel materials increases their hardness and wear resistance.

- **Producing Industrial Electrodes**: Due to its excellent electrical conductivity, graphite serves as the main material in manufacturing industrial electrodes.

- **Reducing Steel and Metal Oxides**: Graphite is used in reducing steel and other metal oxides through carbon reduction.

In summary, graphite and its derivatives play a crucial role in various industries, and their production and supply are of great importance. Hamgaman Sanat Company, with its extensive experience and reputation in global markets, is capable of delivering this product at competitive prices and exceptional conditions worldwide.